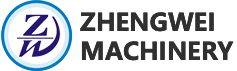

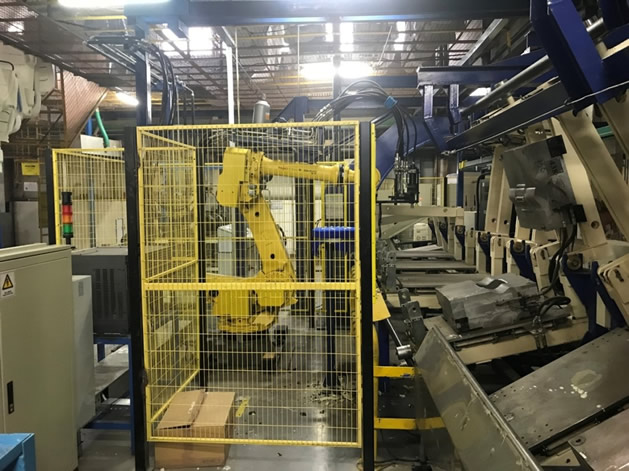

The fully automatic oval foaming production line is specially designed for large-scale automotive seat cushion foaming. Adopting a ground-mounted circular structure, it can be configured with up to 60 stations and features automatically adjustable production takt time. The system adopts robot automatic pouring, enabling mixed-line production of dual-hardness automotive seat cushions and backrests. It is characterized by high automation, safe and reliable performance, and suitability for mass production.

42-station fully automatic pouring automotive seat cushion oval foaming production line

36-station fully automatic pouring automotive seat cushion oval foaming production line

32-station fully automatic pouring automotive seat cushion oval foaming production line

42-station fully automatic pouring automotive seat cushion oval foaming production line

42-station fully automatic pouring automotive seat cushion oval foaming production line

36-station fully automatic pouring automotive seat cushion oval foaming production line

32-station fully automatic pouring automotive seat cushion oval foaming production line

Fully automatic pouring oval foaming production line for automotive interior parts

PIP headrest and armrest foaming production line